Granite Laser Etching Machine

| Product | Granite Laser Etching Machine |

| Laser Source | CO2 and fiber lasers |

| Power | 20W-10KW |

| Brand | Granite Engraving Machine |

| Country | India |

| Packaging Type | Wood Box With Bubble Sheet |

| Delivery Time | 1-2 Weeks |

- Memorials and Monuments: Creating personalized inscriptions, portraits, and designs for gravestones & memorial plaques.

- Architectural Elements: Adding decorative components to architectural granite, often utilized in upscale buildings or historical restoration projects.

- Signage: High-quality, durable signage with the option for customized text & graphics.

- Gifts and Trophies: Personalized, intricate designs for awards, plaques, or keepsakes.

- Interior Design: Adding unique textures & patterns to granite utilized in home or office decor.

Introduction of Granite Laser Etching Machine

A granite laser etching machine is an advanced equipment utilized to engrave, etch, and mark granite surfaces with precision. This equipment utilizes laser technology to create highly detailed images, text, and designs directly onto granite. Often employed for personalized gifts, memorial plaques, signage, & architectural elements, granite laser etching delivers durability & a sophisticated finish. The laser’s ability to handle intricate designs makes it a desired option in industries with certain value durability & aesthetic appeal. We are the largest granite laser etching machine manufacturer in India. We also provide granite carving machines, automatic engraving machine, marble engraving machines, glass engraving machine, etc.

A granite laser etching machine is a laser engraving machine that is specifically built for engraving and etching designs, patterns, and text onto an assortment of stone surfaces, including granite, marble, slate, and others. These machines employ a laser to release material from the stone surface, resulting in the desired design or pattern.

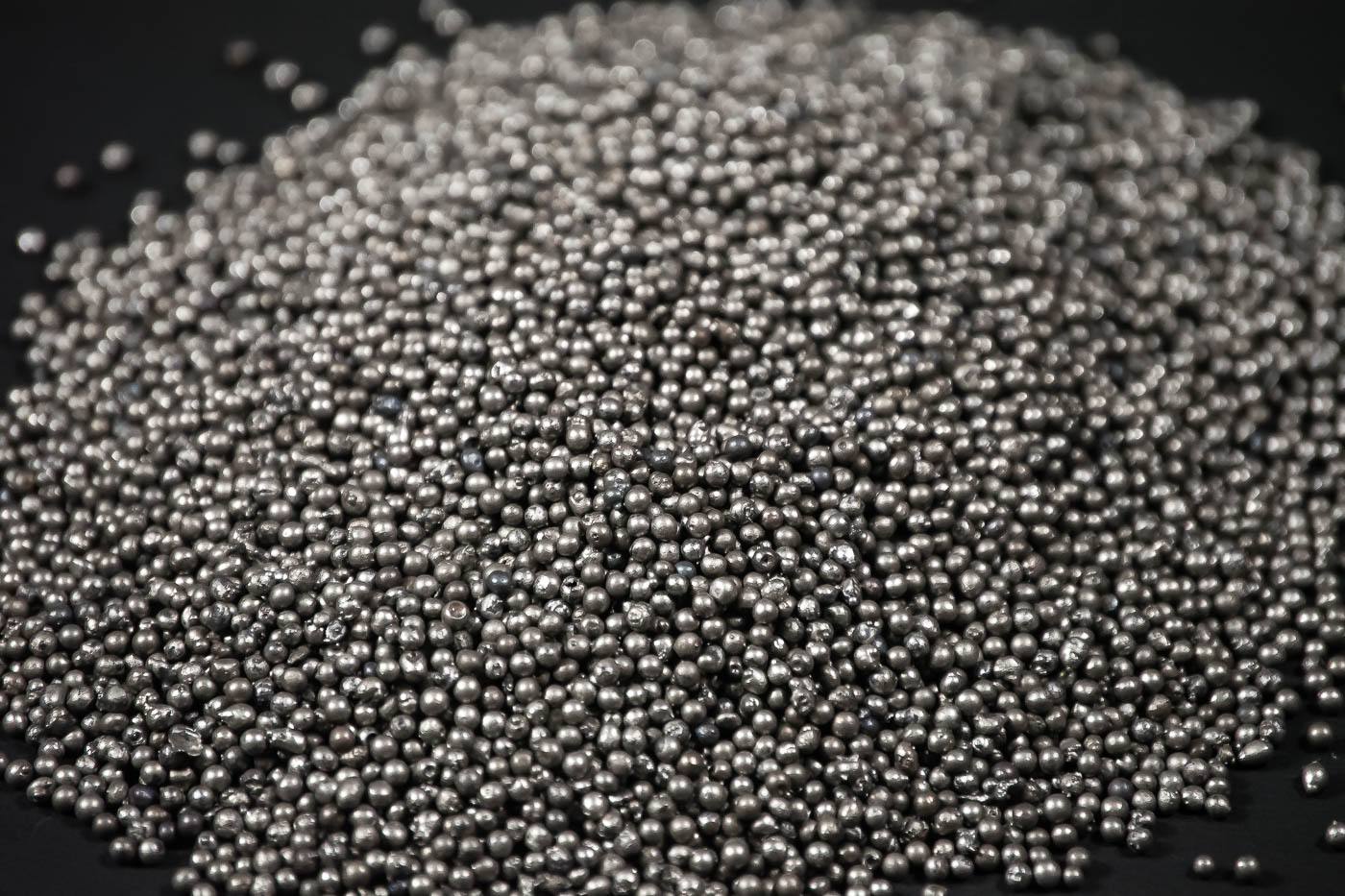

A granite laser etching machine on stone creates a result alike to a sand blasting machine or granite engraving machine: a surface engraving that delivers the impression certain the stone has been bleached. Letters, photographs, & logos could be permanently printed on stone.

A laser etching machine principally comprises four fundamental components: a laser, a manipulator, & a stepper motor. It resembles a pencil - the energy discharged allows the manipulator to create designs on the material. The manipulator with the assistance of a stepper motor determines the heading, force, velocity of development, & increase of the laser energy concentrated on a surface level. The area is specified to correspond to where the laser could follow up.

Granite Laser Etching Machine Working

A granite laser etching machine works by directing a laser beam onto the surface of granite. The elevated-intensity laser concentrates on specific points on the granite, vaporizing the top layer to construct an impression. The depth, intensity, & detail of the etching could be handled by adjusting the laser’s power, speed, & focus. Most machines operate with CO2 or fiber lasers, each offering specific benefits. CO2 lasers are constantly chosen for non-metal surfaces like granite, while fiber lasers are comprehended for fine detailing.

Laser etching is a quicker process, whereas laser engraving is more durable. This is because achieving a material's melting point (laser etching) carries less energy than vaporizing it (laser engraving). Deep laser engraving may necessitate multiple laser passes, which will unavoidably take more time.

On the other hand, engraved holes provide superior abrasion resistance than elevated markings generated by etching. In actuality, the laser etching peak could reach 80 microns, while the laser engraving depth could be 500 microns.

Laser etching is very effective at producing high-contrast marks. A laser etching machine, unlike a laser granite engraving machine, could make both black & white marks. As an outcome, laser engraving is sometimes employed in conjunction with laser etching to produce elevated-contrast engravings.

Types of Granite Laser Etching Machine

CO2 Lasers: Standard for non-metallic surfaces, including granite. They are cost-effective & offer precise results.

Fiber Lasers: Though more commonly utilized on metals, some manufacturers prefer fiber lasers for granite when intricate detailing is necessary.

Laser engraving, in terms of etching on stone, is the technique of releasing the polished surface with a Co2 laser & eternally etching into the naturally uncovered material based on the image parameters. In general words, laser etching, often understood as laser engraving machine, is the equipment of granite stone engraving machines & additional materials utilizing lasers. In this case, we are concentrating on granite monuments. The benefit of laser etching is that it permits you to create realistic photo-like images in the same way that a traditional laser printer can, but with greater precision, which is very important when working with granite monuments and headstones.

Features of a Granite Laser Etching Machine

When selecting a granite laser etching machine, it’s important to consider the features certain will influence the machine’s performance, durability, & versatility. Some key features include:

- Precision and Resolution: The level of detail in etching turns on the machine’s resolution capabilities, typically measured in DPI (dots per inch).

- Speed and Power: Adjustable speed & power settings allow for flexible operation. Higher power allows deeper etching, while adjustable speed helps in managing precision.

- Laser Lifespan: CO2 lasers typically last between 2,000 to 10,000 hours, while fiber lasers include a longer lifespan.

- Size of the Working Area: The machine’s table size specifies the size of granite slabs that could be etched in one go. Standard sizes vary, but larger machines offer more flexibility.

Benefits of Granite Laser Etching Machine

Using a granite laser etching machine offers several benefits:

- Durable Results: Laser etching on granite assembles a lasting impression that is resistant to wear, making it perfect for memorials, signage, and architectural elements.

- Precision and Detail: Laser etching machines provide unparalleled precision, permitting tough designs and detailed images.

- Cost-Effective: Once set up, the machine reduces labor costs by automating much of the etching process.

- High Efficiency: Laser etching is faster than traditional methods, reducing turnaround time on orders.

Granite Laser Etching Machine in India

We are the leading granite laser etching machine manufacturer in India and also the granite laser etching machine supplier all over the world. Compared to others our granite laser etching machine price is low. Apart from granite laser etching machines, we also provide granite engraving machines, portable engraving machine, granite nameplate machines, laser engraving machines, CNC engraving machines, metal engraving machines, laser rust cleaning machine, and more.

Sand Blasting Machine

Quick Enquiry